Chronology and origin of the production of our high-quality shoes

Our company has been active in the shoe production and shoe business since 1985 and, based on this experience, developed this unique product line in 1991, which combines innovative ideas with traditional manufacturing. The result is shoes that are characterized by the sustainability of the product as well as the materials and are manufactured under the strictest social standards exclusively within the European Union. For this it was necessary to redevelop the components such as leather, soles, lasts, cuts, etc. in order to combine the advantages of traditional production with the latest findings from research, technology and the latest production methods.

Classic shoes with a high value due to quality and function

Here you will find classic shoe shapes reinterpreted in sustainable high-quality materials, exceptional workmanship and maximum functionality

This resulted in the natural leather product line that we developed for our shoe production. Our leathers are produced in an environmentally friendly way according to strict requirements and are extremely skin-friendly; the tanning takes place without chromium and heavy metal, without the addition of PCP or formaldehyde; Solvents are no longer contained even in the finish. Despite this gentle refinement of the natural material leather, we have succeeded in meeting the highest technical standards while maintaining the natural character of the hides. The design and development are done in our studios in Munich and Aveiro. The serial standard is being implemented in our production in Portugal. In our products we combine the spirit of time with the principles of convenience, comfort, durability and environmentally friendly production.

The completeness of this concept and the delight in the outstanding sets our product apart from all others and makes it so unique. As a matter of course our high quality shoes are carefully handcrafted being assisted by the finest machinery.

In the interplay between the spirit of the time, the fashion and the functionality of our product, the future concepts, shapes, cuts, colors, materials, soles, heels and components are created in our design studios. For our highly specialized product we develop, select and recheck every single detail. For every shoe, depending on the model, there are 30 to 45 different individual parts that have to be newly developed for each style and mostly also made by hand.

Design and development of our high quality shoes

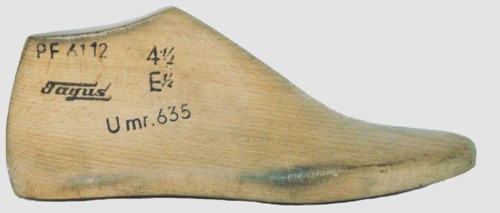

Claus Beeck develops and manufactures both women's and men's shoes. At the beginning there is always the last, which later gives the shoe its shape and thus decides on the appearance as well as the comfort, the size and the fit. A lot of experience about the structure of the foot, i.e. the anatomy, the mobility and the orthopedic basics, is therefore necessary to manufacture the prototype. In addition, there is a feeling for fashion trends and aesthetics. This first prototype is filed by hand from a block of wood. Our lasts were specially designed for the feet of central European, which means that they allow a particularly comfortable width in the ball area of the foot, a comfortable height for the toes and sufficient volume for the instep. The height of the heel has the right ratio to the forefoot so that the feet do not tire even when standing and walking on hard floors for long periods. The foot is not unnaturally constricted; where it is necessary, it gets hold and support through the use of strong materials and the special production method. In addition, in Claus Beeck's shoes, the foot is effectively supported by a replaceable orthopedic insole, in the heel and joint area; the entire appearance is cushioned and cushioned by the specially developed soft bedding. A cut must be made for the leg, i.e. the upper part of the shoe. This is again created by hand for the prototype and gives the shoe its appearance and functionality. In turn, all other components must be developed to match this, such as heels and soles for example, all of which are built by hand. What was conceived and developed in the studios later has to be transferred to production standard. This again requires numerous tests and adjustments. For a better understanding, it should only be mentioned here that the original prototype has to be developed again and again in every size and in every width. That means a new last, cut, sole and so on for each size. Here the extraordinarily complex process of our production becomes clear. It takes about 3 months to develop a prototype until it is ready for series production. The production of a shoe in the well-organized series production takes at least 8 working days, whereby the work steps and components, as well as the soles and the uppers, must be prepared. In detail, the following steps are necessary for the production of Claus Beeck's shoes:

- application of the outsole

- Polishing the leg on the last

- Application of the outsoles

- Removal of coarse adhesive residues

- Sewing the sole and the upper

- Finish with stuffing, threading the laces, scarfing, processing, waxing, brushing, polishing

- Final check

- Packing and shipping.

The details and production steps presented here show that our production, which is largely done by hand, is extremely complex and can take up to 12 weeks. This gives a little insight into the complexity of the art of shoemaking, with which our Naturleder-Schuwerk shoes are still made. This is where our products differ significantly from simply produced and uniform mass-produced goods. Our production facility is located in Portugal. In the factory, our shoes are still handcrafted in a traditional way. Production is supported by machines, while the shoe is still being processed by hand in each work step.

The vast majority of our Naturleder-Schuwerk shoes are made in the state of art shoe manufacturing in sewn lastings; only the gallantry of the women's shoes are assembled by hand and not additionally sewn between the upper and the sole. The men's shoes are sewn with traditional craftmenship, with the upper leather leg being connected to the sole with an additional sturdy seam. This gives the shoe more stability and, with the appropriate care, a longer lifespan, making the shoes even more comfortable. The additional reinforcement through the seam supports the natural rolling movement of the foot. Each of our Naturleder-Schuhwerk shoes is made with selected chrome-free tanned natural leathers. This is a traditional type of leather finishing that is particularly durable due to the gentle and time-consuming nature of the traditional recipes. This tanning gives the leather suppleness and, in the method developed by Claus Beeck, through fatliquoring and mechanical fulling, its softness and a warm feel. Regular re-greasing of the shoes gives them their original temperature-regulating effect, i.e. cooling in summer and warming in winter, as well as the water-repellent effect. Due to the complex and gentle tanning process, the leather fibers are "coated" and not attacked by the tanning agent. Our natural leathers are tanned without harmful chemicals, which makes them different from other products. The coloring is also done without the use of toxic heavy metals, PCP, formaldehyde, glyoxal or the like. This should actually be a matter of course, but the use of these substances is still common worldwide even for high-priced branded products. Thanks to the special tanning, our leathers retain the natural properties of the skin, i.e. they are particularly breathable and temperature-regulating, they are dimensionally stable, skin-friendly and can be composted without leaving any residue. This is the secret of the outstanding wearing characteristics of the Naturleder-Schuwerk products. Of course, our Naturleder-Schuwerk shoes are particularly suitable for barefoot wear. In order to achieve the best possible foot climate in combination with the breathable leathers, we have designed the shoes accordingly. Our natural leathers are finished and polished by hand, which creates a depth of color in the upper leather that is no longer possible with conventionally coated leathers due to the synthetic surface finishing. In our Naturleder-Schuwerk products, the insole of the shoe is made of geniuine leather in principle. This has the advantage that the moisture in the shoe is absorbed much better. The leather releases the moisture in the shoe and does not accumulate it. Because of this high quality standard, the shoes are always completely lined with high-quality leather right up to the tip of the shoe. This is also a big difference to most brand name shoes nowadays, which for cost reasons only use synthetic textile materials in the shoe's front sheet, even with so-called leather lining. We also do not use chemical products to fix the dyeing substances, which also improves the water vapor permeability of natural leather. This can lead to bleeding of the lining leather. We ask our customers to take this into account when choosing their socks and stockings and, in such cases, recommend the use of dark goods.